High Volume Transfer Systems

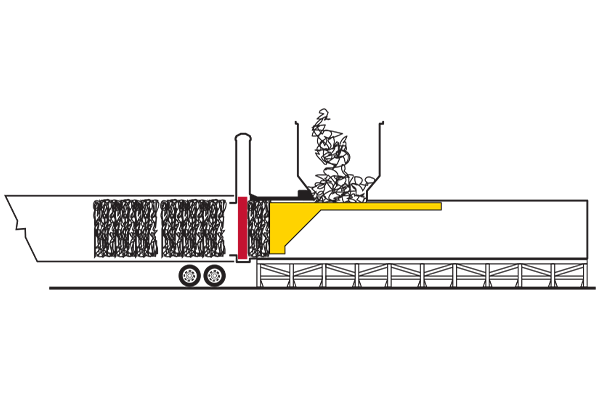

The Marathon® high volume transfer station compactor systems can process up to 90 tons of material per hour and compact materials directly into transfer trailers. Multiple options are available to suit various applications.

Have Questions About High-Volume Transfer Station Compactors?

Contact your local Marathon® Compaction team today to request a complimentary site survey.

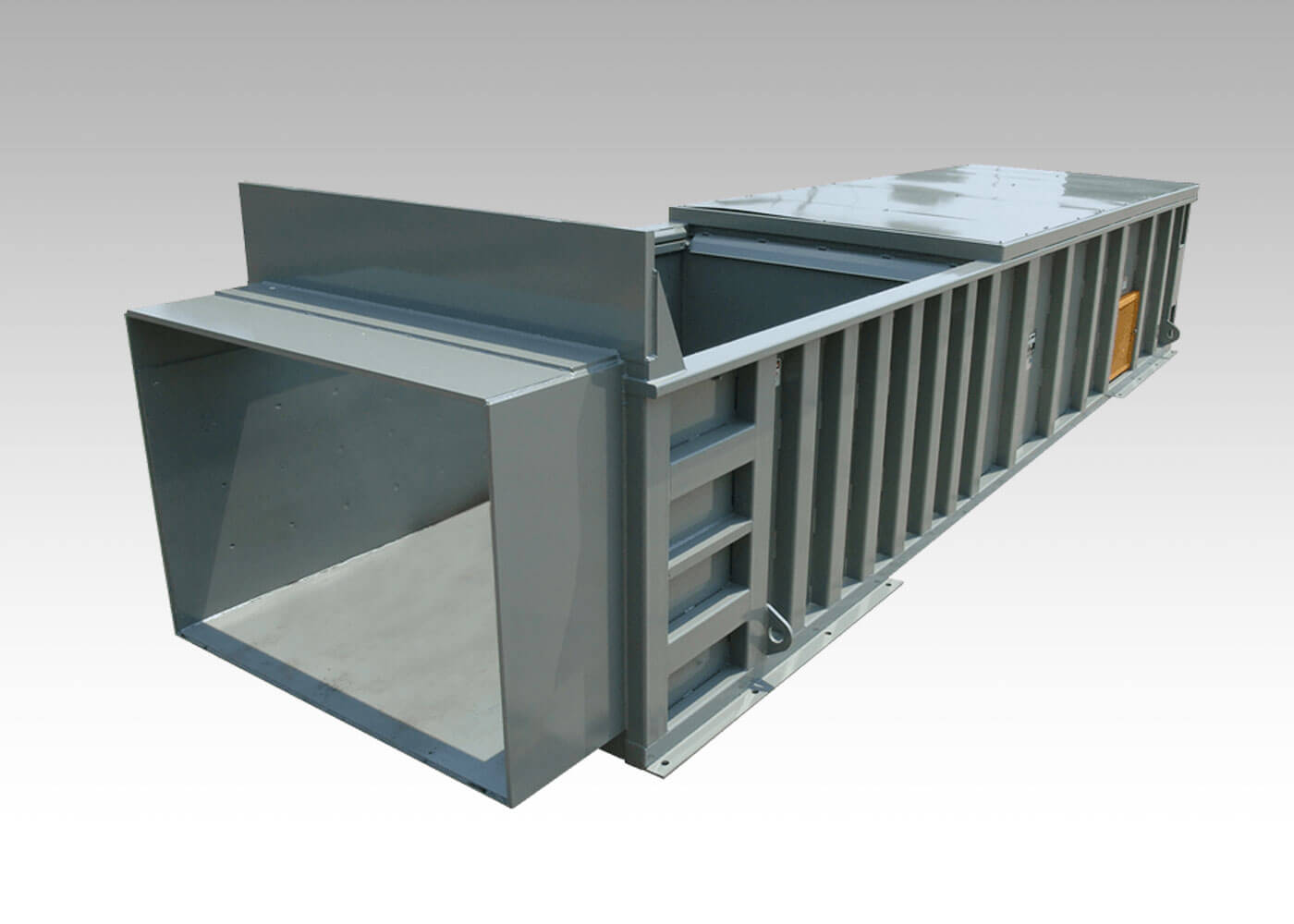

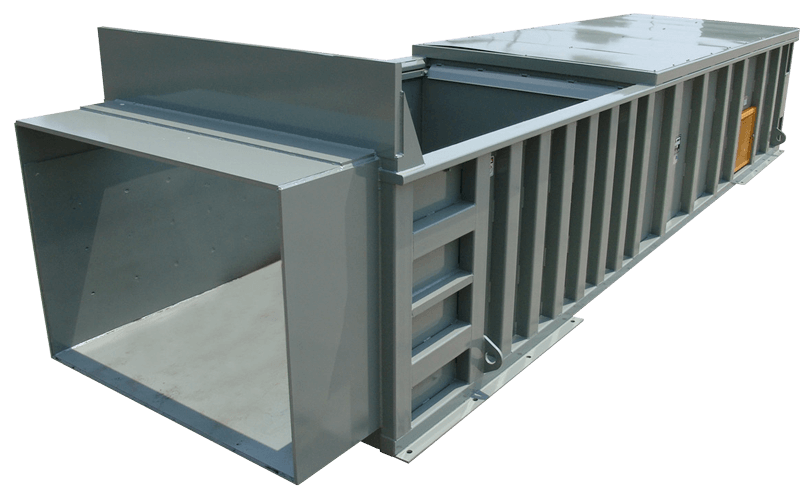

BlokPak 3000® Transfer Station Compactor

The BlokPak 3000 is the largest Marathon transfer system compactor. It compacts waste against a vertical gate, forming a 10′ (3 meter) log in the compaction chamber. Each log is then ejected into the transfer trailer, and the process is continued until maximum payload is achieved. When the trailer is full, the BlokPak 3000 can continue to be fed while changing trailers, saving valuable time. This unique design eliminates the need for expensive ejection type trailers.

The BlokPak 3000 forms 10′ (3m) logs of densely packed waste.

The BlokPak 3000 has a 5′ (1,5m) ram penetration. This ejects the final log into the trailer with very little spillage.

The BlokPak 3000 has a compaction chamber that densely compacts the waste before it’s ejected into the transfer trailer. This enables much lighter-duty, open-top trailers to be used.

BlokPak 3000® Transfer Station Compactor

The BlokPak 3000 is the largest Marathon transfer system compactor. It compacts waste against a vertical gate, forming a 10′ (3 meter) log in the compaction chamber. Each log is then ejected into the transfer trailer, and the process is continued until maximum payload is achieved. When the trailer is full, the BlokPak 3000 can continue to be fed while changing trailers, saving valuable time. This unique design eliminates the need for expensive ejection type trailers.

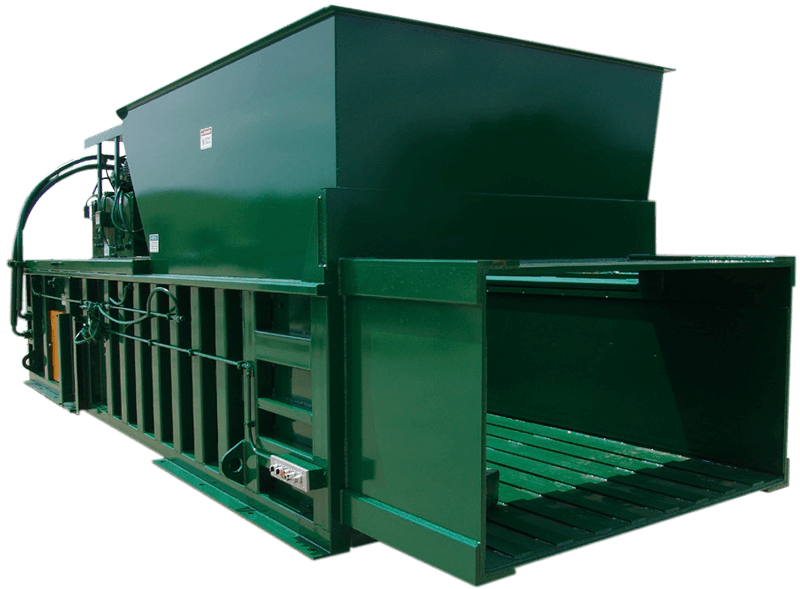

Rawhide Series®

The Rawhide Series is a special option that can be applied to the M-Series 1050 and 1475 Compactors. It has a 48″ ram penetration that is especially beneficial for packing out transfer trailers for a clean breakaway.

Optional Waste Transfer Station Equipment

Marathon Transfer System Compactors can be fitted with a variety of options, such as trailer connection systems, to suit your application. The hydraulic scissor extends to connect to the trailer’s vertical pin latch. The hydraulic grab claws hold the trailer, using their side pockets. Marathon also manufactures EZ-TRAX® Conveyors for an efficient way to feed your transfer system. Load cells can be utilized to keep track of the weight as the compaction trailer is being loaded to maximize payloads.

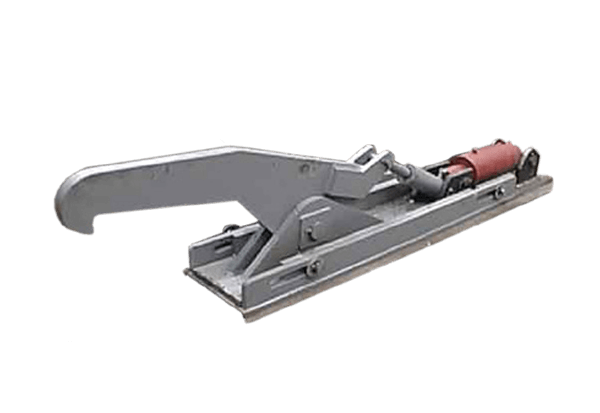

Extending Hydraulic Scissor Connector

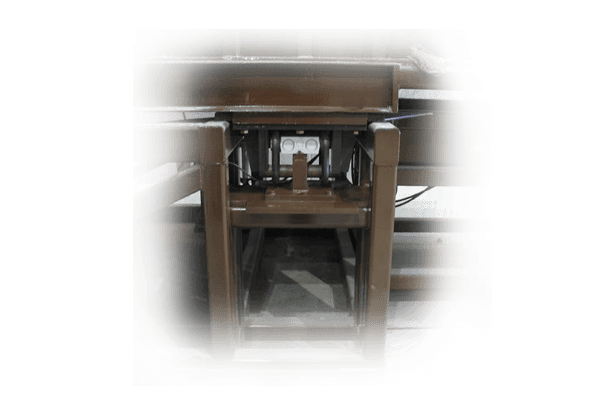

Hydraulic Grab Claws

Hydraulic Grab Claws

EZ-TRAX® Conveyor System

Load Cell Weighing System

Compaction Options

The perfect configuration for your specific needs

Options are an essential part of virtually any compactor installation. Whether the options are for safety issues, convenience, operation efficiencies, or monitoring systems, waste-handling equipment can be fitted with a variety of customizable features to meet the demands of the application. Marathon compactor options include several categories such as: container-fullness measuring systems, usage-measurement systems, cycle-control systems, power pack options, odor-control systems, and steel options.

View Compactor Options